Safety-Film

Sicherheitsscheiben für Werkzeugmaschinen

your Challenge

Due to cooling lubricants, chipping or UV-radiation, unprotected polycarbonate panes quickly lose stability, retention and safety. In order to reduce possible dangers as well as downtimes, labor law requires to check safety properties of the pane on a regular basis, and if necessary, to immediately replace them in any case of damage.

Our Solution: Chip Protection Foils

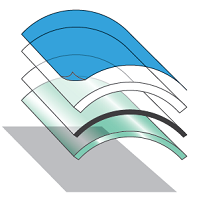

Due to extremely resistant and highly transparent materials, our product SAFETY-FILM succeeds in reducing downtimes significantly. Key to this success is a composition of plastics and foils. Those foils as a base create a strong bond with polycarbonate, and at the same time, can be removed as sacrifacial foils (foils are mounted as layers). In addition to other advantages, a clear view is always guaranteed.

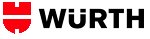

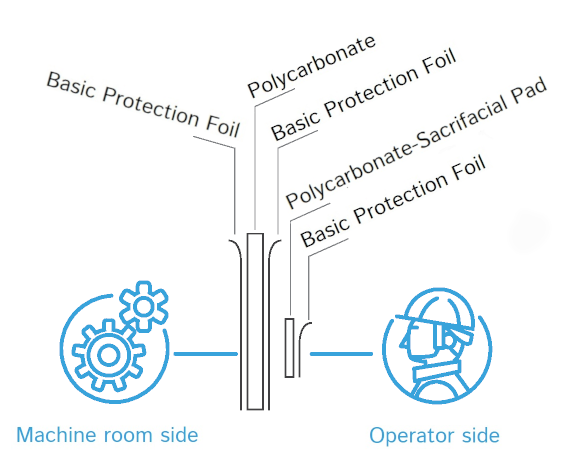

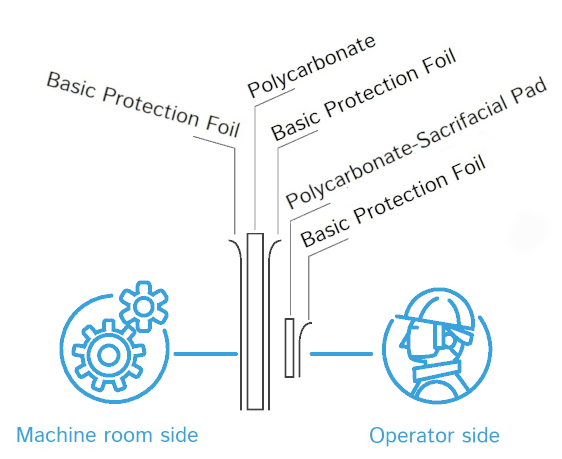

Polycarbonat-Sicherheitsscheibe compounded with chip guard foils

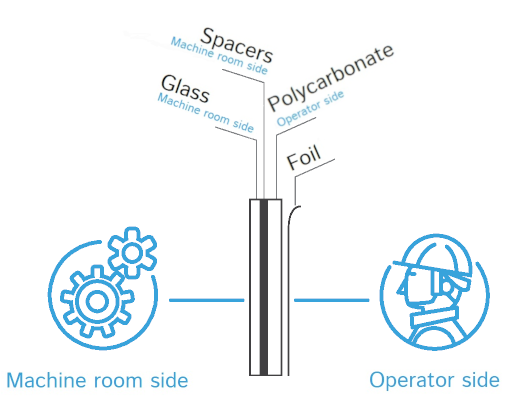

Machine room side

- Polycarbonate pane with special film 100µm to 150µm thickness, surface-hardened coated

- Additional: wear-protection film 150µm, 175µm, 200µm thickness (removable)

- Can be coated in single or multiple layers

- Already worn layers can effortlessly be renewed and individually reordered here: Accessories

Operator side

- Polycarbonate panes with special film 100µm thickness, surface-hardened

- Protection against UV-radiation and exposure to vapors and cleaning supplies

Advantages of coated plastic PC panes

- Safety at Work

- Longer Lifetime

- Reestablishment of clear view

- Cost savings, since replacement intervals of the PC panes can be increased.

Application Fields

- Machining Centers

- CNC - Machines

- Turning Centers / Lathes

- Machine Construction

- Sandblasting Units

- Test Stand for Brakes

- Food Industry

- Ampoule Filling Systems, and many more

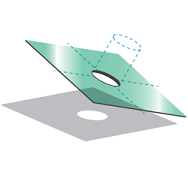

Curved, drilled or any other configuration: Top Seal offers individual CAD-designed panes. Get your individual safety glass projected in CAD!

Safety-Glass

Sicherheitsscheibe für Werkzeugmaschinen

your Challenge

Often, machine manufacturers only equip their units with simple polycarbonate panes. Since polycarbonate is sensitive to cooling lubricants, chipping and UV-radiation, it regularly must be replaced due to rapid wear. This results in downtime and less efficiency, with could be avoided.

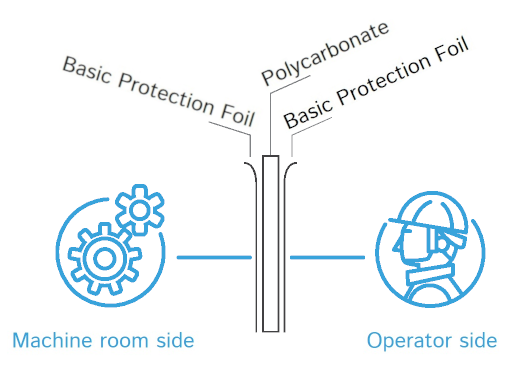

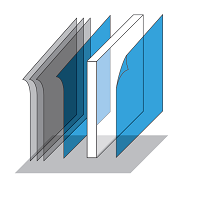

Full Composite

Air gap (LZR)

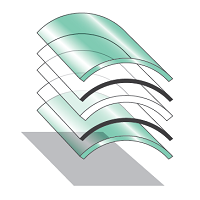

Multiple Full Composite

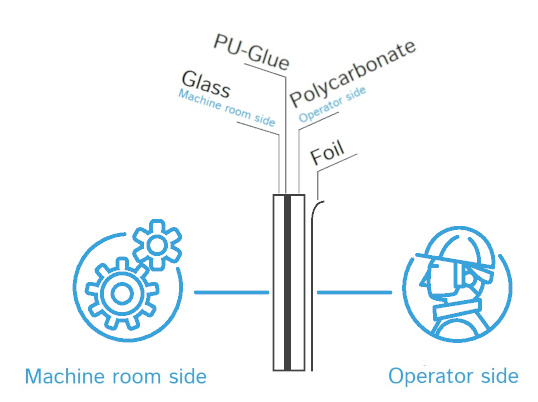

Our Solution: Multilayer Glass

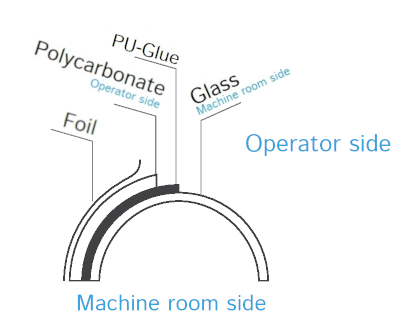

Top Seal SAFETY GLASS is a composite of safety glass and polycarbonate. Machine room sided, our product is made of safety glass, on operator's side it consists of polycarbonate and safety film, bonded with a special PU adhesive or with our unique air gap technology. So, darkening of the pane, caused by cooling lubricants or chipping is significantly delayed. At the same time, safety requirements for staff members are quaranteed through resistant materials.

Full Encapsulation Composite vs. Air gap (LZR)

Our SAFETY-Glass is manufactured in two main construction types, each offering specific advantages:

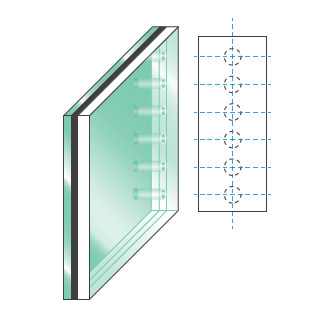

Full Encapsulation Composite

- Full Encapsulation Composite

In this construction, polycarbonate and safety glass are fully bonded using a special high-performance adhesive (PU adhesive). This creates a robust, uniform structure that meets the highest safety requirements. The adhesive ensures that the two materials form an inseparable unit, enhancing the pane's stability and durability.Benefits of Full Encapsulation Composite

- Protection Against Chemical Influences: The special adhesive prevents coolants or other chemicals from reaching the polycarbonate, significantly extending the pane's lifespan. This is particularly important, as studies show that polycarbonate alone can age rapidly due to coolants, with a reduction in retention strength of up to 60% after nine months.

- Enhanced Retention Capability: The complete bonding of polycarbonate and safety glass increases the pane's stability and improves its ability to retain impacting projectiles (e.g., chips or workpieces at speeds up to 190 m/s).

- No Shard Formation Inside the Machine: In the event of an impact, glass shards remain adhered to the pane due to the adhesive, preventing machine downtime and potential damage inside the machine tool. This reduces downtime and enhances operational safety.

- Air gap

In this variant, an air gap remains between the polycarbonate and safety glass without the use of adhesive. The safety glass protects the polycarbonate from external influences, while the air gap provides a cost-effective and proven solution.Benefits of Air gap

- Cost-Effectiveness: This construction is generally more cost-effective than the full encapsulation composite, making it attractive for applications with limited budgets.

- Effective Protection: This cost-effective variant provides proven and reliable protection for both the polycarbonate against chemical influences and the machine operator, performing just as well as the full encapsulation composite.

| Characteristic | Full Encapsulation Composite | Air gap |

|---|---|---|

| Chemical Protection | Excellent due to adhesive | Good due to safety glass |

| Retention Capacity | Very high due to bonding | High, but lower than full encapsulation |

| Cost | Higher due to complex manufacturing | More cost-effective |

| Shard Formation | None, as glass shards remain adhered | Possible shard formation upon glass breakage |

| Lifespan | Longer due to polycarbonate protection | Shorter, depending on environmental influences |

Sustainability and Cost Savings

Profit for both: you and the environment! Top Seal relentlessly strives to support sustainability by reusing plastics three or four times. Just send us your defect pane and we will replace it by re-using the plastic components. (The pane must be in flawless technical condition without being affected from splintering, cooling liquids or lubricants)

Curved, drilled or any other configuration: Top Seal offers individual CAD-designed panes. Get your individual safety glass projected in CAD!

Top Seal Special Solutions

Curved

Top Seal offers safety panes in all shapes and designs like special curving or any other geometry on request. Dont' hesitate to contact us or use the contact form to enter all mandatory information!

Drilled

We are offering safety panes with any drilling pattern - contact us with a detailed description to get our very competitive offer.

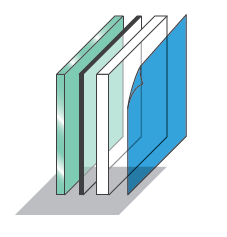

Frames

Complete Protection Window

Top Seal offers Safety-Glass and stainless steel frames combined as a complete safety window. The pane is surrounded by the frame and thus, sealed sidelong. The windows are tailored precisely to their operating environment.

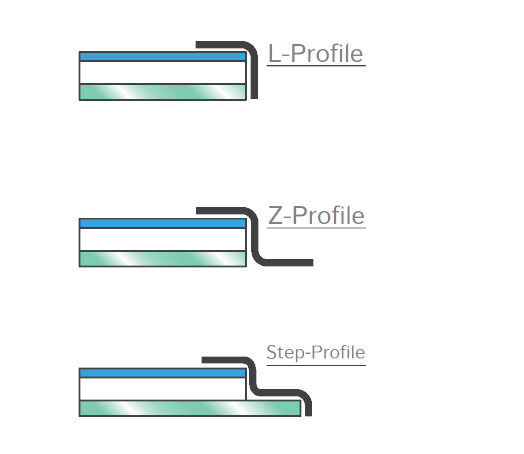

Stainless steel frames are available in various designs with L-, Z- and step-profiles

Replacement Frames

In order to lower your costs, we'll accept your pane in part-exchange depending on its condition.

Sacrificial Pads & Sacrificial Foils

Sacrificial Pads

By applying special techniques, Top Seal uses sacrifacial pads in addition for particularly high stressed areas of the pane. This not only results in higher protection, but also in cost savings because you only have to replace the pads instead of the safety pane itself.

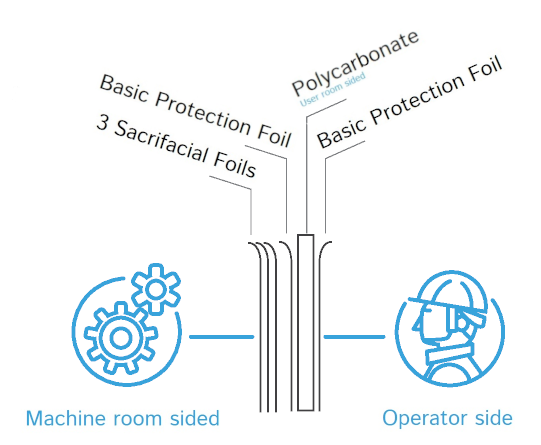

Sacrificial Foils

If you want to clear your pane from smudging and scratching, additionally order sacrificial foils to protect it (machine-side faced) from dirt and damage.

Gluing Sets

In case you are interested in gluing protection panes on your own by your professionally trained staff, we are offering the necessary equipment for installation.

Selected the accessory here to add them to the application form. There you can adjust the amount of items in order to get an offer..

Machine Protecting Panes

Current Standards:

DIN EN 12415 refers to lathes or rotation centers and classifys the isolating protectors into 9 groups.While DIN EN 12417 relates to machining centers, DIN EN 13218 deals with test methods of machine tool safetyfor stationary grinding machines.

Each PC test item (500 x 500 mm) ist vertically shot by one projectile.If no projectile oder part of it penetrates the test item, the test ist considered as passed.

Standard EN 12417 takes a different approach: a test item (100 g) is shot. So, velocity is calculated from rotational speed and diameter of the chuck.

{% trans "Für die Norm EN 12417 haben wir vier kundenspezifische zugelassene Verbunde. More can be adjust at any time.

Standard DIN EN 12417

| Resistance Category | Chuck [mm] | Weight ± 0,1 [g] | Projectile Velocity [m/s] | Energy [J] |

|---|---|---|---|---|

| A-1 | bis ∅ 130 | 625 | 32 | 320 |

| A-2 | bis ∅ 130 | 625 | 50 | 781 |

| A-3 | bis ∅ 130 | 625 | 80 | 2000 |

| B-1 | von ∅ 130 bis ∅ 250 | 1250 | 50 | 1562 |

| B-2 | von ∅ 130 bis ∅ 250 | 1250 | 63 | 2480 |

| B-3 | von ∅ 130 bis ∅ 250 | 1250 | 80 | 4000 |

| C-1 | von ∅ 250 und < | 2500 | 50 | 3124 |

| C-2 | von ∅ 250 und < | 2500 | 63 | 4960 |

| C-3 | von ∅ 250 und < | 2500 | 80 | 8000 |